© 2002 The Independent Fact Group

![]()

![]()

©

2002 The Independent Fact Group

|

The Commission: "A hole due to an impact by the lugs of the starboard manual lock was noted in the front bulkhead just above the starboard side lock" |

| Subject: | Non conclusive damage explanation |

| Type: | Analysis |

| By: | The Independent Fact Group |

| Status: | Proved |

| Date: | 2002-12-24 |

| Version: | Report - English |

The Fact Group's aims and objectives:

The Independent Fact Group was formed in early 1999 to clear up the many question marks about the MV Estonia disaster, in a structured and methodical manner. There has been considerable speculation concerning the efforts of the Joint Accident Investigation Commission (JAIC) and the political, legal and media treatment of the accident and its tragic consequences.

The aim is to give those in authority an opportunity, based on the facts of the case, to decide to review this matter, with a view to further action. Our efforts also enable the media and the general public to decide on the basis of the objective information which is available concerning the accident, and the conclusions to be drawn from a technical and civic perspective.

The overall objective is the setting up of a new investigation of the accident which can describe the course of the accident in detail, and its causes, with subsequent assessment of the moral and legal responsibilities, where this is feasible.

We are motivated by the belief that a properly conducted investigation will contribute to maritime safety and by our concern for Sweden's reputation as a nation which upholds safety at sea and the rule of law.

Methodology:

In the course of this task, we have assumed that the solution of a problem is never better than the validity of the basic assumptions. As a result, we have stipulated some methodological principles, of which the following are the most fundamental:

1. All scenarios must be considered to be true until the contrary

is proved.

2. All observations, assumptions or statements on which a scenario

is based must be considered false until the contrary is proved.

We have defined a number of criteria for concluding that an observation, assumption or statement may be considered to be true or false, and processes and routines for the route to be taken in clarifying an observation, assumption or statement. These criteria involve technical, empirical, statistical and/or semantic requirements which, if they are relevant must all be met if the observation, assumption or statement is to be classified as an objective fact.

The materials we have worked with are primarily the documents, audio recordings and films in the Swedish Accident Investigation Commission's Estonia archive, together with supplementary information from other public sources and, in addition documentation from the Meyer shipyard and its independent commission.

Summary

First and foremost we want to clearly state that the JAIC in their

final report have not been able to show that any forward forces

big enough to break the visor loose existed. It is of outmost

importance that the JAIC scenarios discussed in this report are

no reflections of the views of the Independent Fact Group - we

are in this report occasionally only playing with the thought

that big enough forward forces did exist during the accident.

(Regarding forward forces, se our report "Impossible visor scenario" ).

In this report, the Independent Fact Group show that JAIC's explanation regarding damage above the starboard visor locking lug is incorrect. Furthermore, when analysed, the damage cannot have occurred unless the starboard visor locking lug itself was detached from the ship when the damage happened. There is just one "minor problem", the visor locking lug is still attached to the ship.

It was reported by JAIC that the lug remained in it's locked position in the bulkhead when found after the sinking. In this position it was not free to move in such way that it could have caused the damage, and it was also in its way for the manual locking lug to get ample room to cause the damage.

This report shows that the damage must have been caused from

the visor locking lug (not from the manual locking lug) and that

the visor lug must have been detached from the ship when it caused

the damage.

Definitions of certain language marks used in this report:

Text presented from the JAIC final report and its supplements is quoted as printed.

Our comments, explanations or clarifications, within quotes, are presented within square brackets [ ].

Text in quotes that has no relevance for the issue at hand has been left out and is indicated by a number of dots ".....".

We have underlined certain sentences and words, to mark their importance.

Background, the loss of the visor according to JAIC

|

JAIC 13.5 Failure sequence of bow visor and ramp: The main failure is believed to have happened in a subsequent wave impact, shortly after the metallic bang. In this main failure the remaining locking devices failed completely, allowing the visor to open partly. Once the visor had lifted off its locating horns, the port side hinge failed under the overload generated by the high twisting and yawing moments and the vertical force. The starboard side hinge failed as a result of twisting when the visor was rotating clockwise. Hydrodynamic loads pressed the visor against the front bulkhead along which it slid upwards. The hydraulic lifting cylinders may have failed at the same moment or may have remained connected for some further time. The port side actuator, which at some stage was pulled out of the hull by failure of the already weakened bottom mounting platform, had extended by about 0.4 m at least. The starboard side actuator failed hydraulically but remained connected and was ripped out of the hull, fully extended, as the last physical connection between the visor and the hull. After the locking devices and hinges had failed and the actuators had lost their restraining effect, the visor had a natural tendency to tumble forward due to its forward-located centre of gravity relative to the new centre of rotation, i.e. the stem post area. The visor's position was at this stage governed by the actuators and the actuator attachment lugs on the hinge beams, protruding into openings in the forecastle deck. The visor was thereby constrained in the longitudinal direction. Subsequent wave impacts caused the visor to move backwards and forwards in combination with some vertical movements, resulting in various impact damage to the bulkhead and the hinge beams. Impact marks indicate violent transverse movements, and upward movements of about 1.4 m. The damage is described in detail in Chapter 8." |

|

JAIC 8.6.2 The visor side locks: The lugs had separated from the visor by shearing of the visor plating around the attachment welds, leaving rectangular holes in the visor bulkhead plating (Figures 8.19 [port side] and 8.20 [starboard side]). The tear pattern and deformation of the bulkhead generally indicated that the lugs had been torn off in a downwards and aft direction." |

JAIC" Figure 13.6 Probable failure sequence of the bow visor." (This figure in high resolution in a new window)

Note that the scenario described in JAIC figure 13.6 does not include any "upward movements of about 1.4 m". JAIC does not explain how the visor could fall forward and rip the ramp and forward bulkhead simultaneously as the visor when fully detached could "jump" 1.4 meter up and backward to cause the damage analyzed in this report.

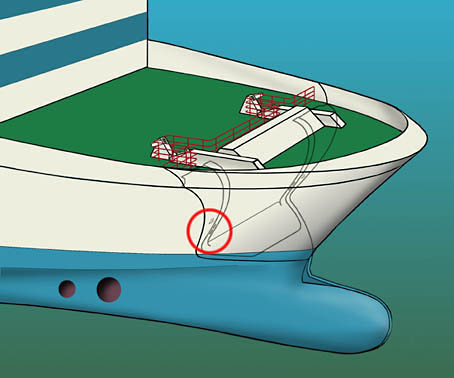

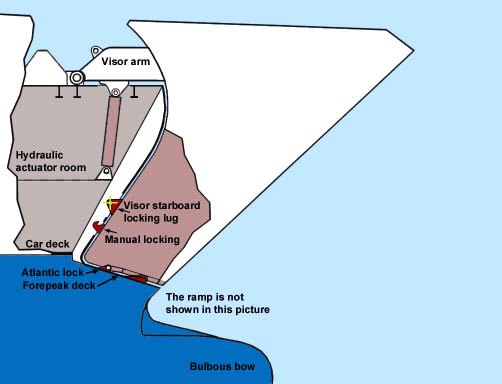

In the following picture we show the presumed visor position

according to the text in JAIC 13.5 and 8.6.2. (which is missing

in JAIC figure 13.6)

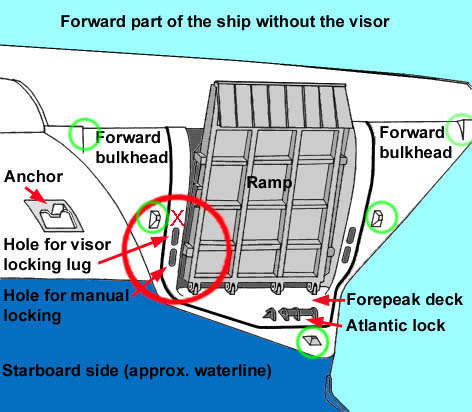

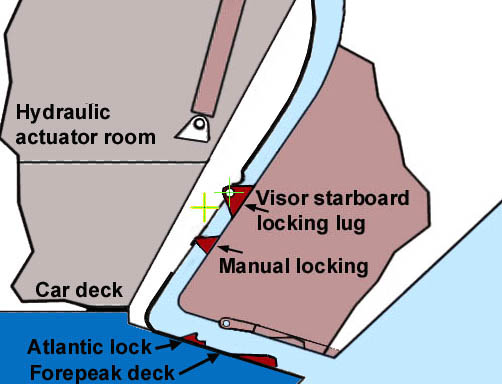

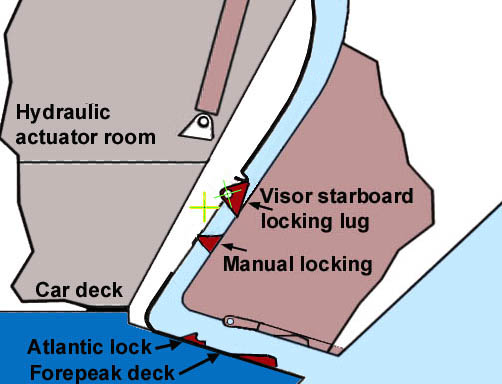

Picture 1. According to JAIC, after the visor was fully detached from the ship (1), it must have moved some 1.4 m upward (2) and then moved backwards penetrating the bulkhead with the manual locking lugs (3), and then, again moved upwards to cause the damage in an upward/forward direction (4).

Description over the damage area

To understand how the damage may have been caused, we must

take a closer look around the damage on the starboard (right)

forward bulkhead (the "wall" between the ship and the

visor). In the following picture 2 the front of the ship is seen

in an angle similar to the very first picture in this report.

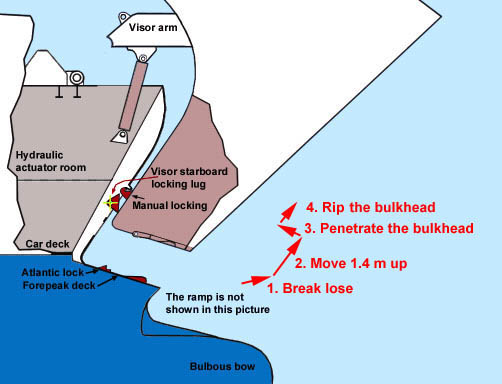

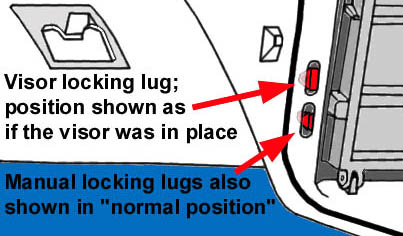

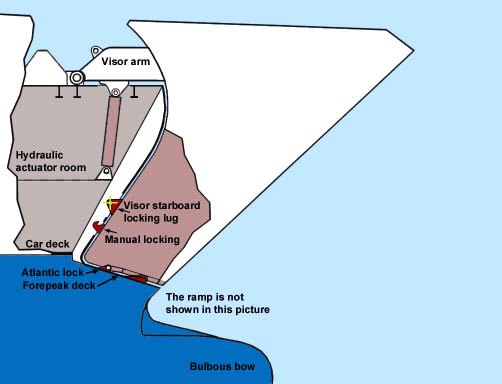

Picture 2. The damage X has occurred

just above the hole for the visor locking lug within the red circle.

Within the lower green circles three locating horns, one on the

forepeak deck and two on the front bulkhead are shown. They engaged

recesses in the visor in order to guide the visor to its proper

position when being closed and to absorb all side loads. The upper

two circles show that the visor was designed to support side loads

also at the deck level, never identified by JAIC.

Picture 3. The visor locking lug measured 60 x 380 mm (JAIC

8.6.2) where it was welded to the aft bulkhead of the visor. The

manual locking lugs at each side consisted of two plate lugs welded

to the aft bulkhead of the visor and an eye bolt in a cavity in

the hull, so arranged that it could be rotated to position between

the lugs and tightened.

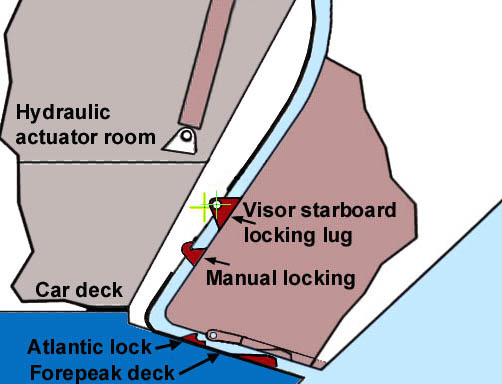

Picture 4. This is the normal locked position of the visor such as it was presumed to have been during the loss of the visor. The manual locking was according to JAIC not used on the last trip, but the visor locking lugs (i.e.. the visor) were locked to the ship by hydraulic pins.

|

JAIC 3.3.2: Three locating horns, one on the forepeak deck [shown in picture 2] and two on the front bulkhead, engaged recesses in the visor in order to guide the visor to its proper position when being closed and to absorb lateral loads. The visor was supported vertically in the closed position by the two deck hinges and rested further on three points on the forepeak deck. One of these was the solid stem post of the visor, resting on the ice-breaking stem on top of the bulbous bow, the other two were steel pads on the forepeak deck. The three locking devices kept the visor down in its closed position and the locating horns absorbed any side loads that might develop. Longitudinal loads were carried by the hinges, the locking devices and possibly by direct contact between the visor and the front bulkhead of the hull." |

JAIC never identified the supportive upper design of the visor shown in picture 2. Further facts regarding the visor arrangements can be found in the Fact Group report "Impossible visor scenario".

General description of the damage

The damage, located immediately above and "starting from"

the visor locking lug (still attached to the ship but detached

from the visor). The bulkhead plating has been deformed in upward

and forward direction causing an "eye formed" and protruding

damage.

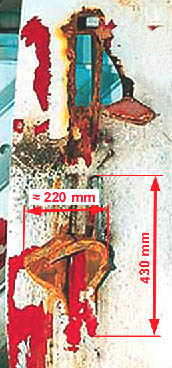

Picture 5. The damage seems to have been caused when the visor

locking lug hit the bulkhead during the loss of the visor. However,

the problem is that the visor locking lug was known to have been

detached from the visor and still attached in its "normal

locked position" in the bulkhead. In such position it can

newer have caused the damage, not even if it was rotating around

its locking pin.

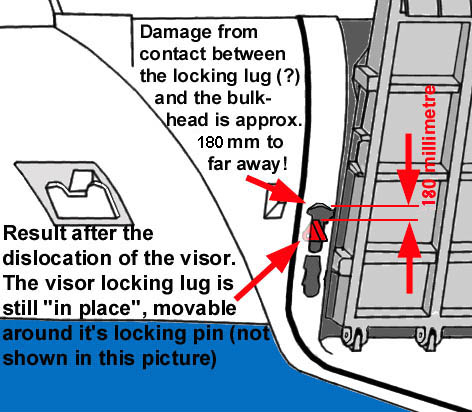

Picture 6. This is a mosaic of photos showing the front bulkhead

and the damage. The damage is seen as if you were standing in

front of the ship ready to enter the car deck. It can clearly

be seen that the damage is caused in an upward direction from

the visor locking lug. The bulkhead has not been hit by the visor

in this area, as the damage in such case should have been an indentation

in the bulkhead. The detail to the right in this picture show

with green marking the holes for the manual locking (lower) and

the visor locking lug (upper). In the upper hole the visor locking

lug points out from the bulkhead marked in red. The length of

the damage in vertical direction is estimated to 180 mm.

Picture 7. The same bulkhead area is seen in perspective view slightly from above. This view was first seen after the August 2000 divings. It can clearly be seen that the damage is protruding forward from the bulkhead. The protruded height of the damage from the flat bulkhead is estimated to 100 - 150 mm. If this damage had been caused when the manual locking lug on the visor hit the bulkhead as concluded by JAIC, the damage naturally should have been an indentation pointing the opposite direction, backward relative to the ship.

Let us take a close look at the manual locking lugs to further

understand weather or not the lugs may have caused the damage.

Picture 8. This is the port side manual locking lugs (still almost intact on the visor). The upper hole (380 mm) is where the visor locking lug were welded to the visor. The vertical hight 180 mm, corresponding to the damage in the bulkhead, has been marked on the manual locking lug. This measure correspond to the minimum vertical indentation that should have been the result, if an intact lug had hit the bulkhead.

The bulkhead does not show this kind of damage. The complete vertical measure of the damage is 180 mm but if the damage had been caused by an intact lug, it should have penetrated the bulkhead further down and then with extreme power and speed ripped the bulkhead open in an upward/forward movement, causing booth a damage in the bulkhead and damage to the lugs.

The detached visor locking lug still remaining in the bulkhead just below the damage, prevented the manual lugs to get ample room to penetrate the bulkhead below the damage and then rip it up. There is no indication of such damage below and immediately besides the visor locking lug.

The damage should have been an indentation rather than the

found damage in upward and forward direction relative to the bulkhead.

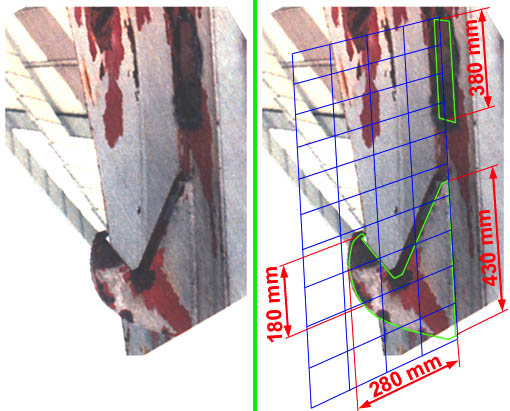

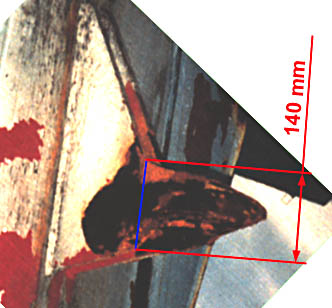

Picture 9 and 10. This is the starboard manual locking lug consisting of two identical lugs welded beside of each other. As can be seen in the left picture 9 the damage is similar in form to the damage (hole) in the bulkhead. The damage is estimated to measure some 220 mm wide and 140 mm high and could very well "fit the damage".

If the lugs already were damaged and then hit the bulkhead, they would have "punctured" the bulkhead alternatively just made an enormous indentation without any ripping of the bulkhead. It is not possible that the damaged lugs first should have fit in below the damage area and then cause the damage in the bulkhead - there is just not enough room for that, as the damaged lugs were to wide and the visor locking lug was in the way of such scenario.

From what is shown above, it must be concluded that the damage was not caused from the manual locking lugs hitting the bulkhead as described by the JAIC.

The two possible (but "impossible") scenarios

1. Visor locking lug damage

The condition regarding this scenario is that both the visor

locking lug and the manual locking lugs were unlocked when the

visor detached from the ship. The damage is caused by the visor

locking lug.

Picture 11. The visor in normal locked position. The manual

and visor locking not locked.

Picture 12. The Atlantic lock and the upper visor hinges has

broke. The visor is moving forward and upward and the manual locking

lugs hit the bulkhead and begin to be deformed.

Picture 13. The manual lugs have been deformed and the visor

has moved further up where the visor locking lug hit the bulkhead

and start to rip it up.

Picture 14. The visor is fully detached and the manual locking lugs are deformed. The visor locking lug has deformed the bulkhead (the damage) and start to brake lose from the visor, ripping itself out from the visor in a rotating motion.

2. Manual locking lug damage

The condition regarding scenario 2 is that both the visor locking

lug and the manual locking lugs were unlocked when the visor detached

from the ship. Other conditions are the same as presumed by the

JAIC, namely that the visor broke lose from the upper hinges and

from the Atlantic lock and thereafter moved upwards. The damage

is caused by the manual locking lugs.

Picture 15. In some way the manual locking lugs enters in through the upper hole that is the normal position for the visor locking lug (green). The visor locking lug must at that time have been "out of place", otherwise there had not been any room for the manual locking lugs to enter (see the left picture). The lugs (and visor) thereafter moved with high speed straight up and the damage was caused similar to what is illustrated in the other pictures in this sequence.

Picture 16. This picture show a transparent projection of the deformed manual locking lugs and how they fit the damage. Note that the deformed lugs fill out the hole completely, i.e. there were no room to generate the initial upward motion that could cause a protruded damage.

Further facts

The following two pictures clearly shows the damage above the

visor locking lug, and that there is no damage besides of the

visor locking lug.

Picture 17. The damage (ripped plating) has started close to

the visor locking lug within the circle A, and continued further

up at B and C. The main contact causing the damage was within

the circles D.

Picture 18. The main contact point are further shown by at

least two contact marks within the upper circles in this picture.

The bulkhead plating has been bent after deformation, most likely

from contact with the visor locking lug.

Conclusion

The damage imposes further "impossible" and unpleasant facts in the following conclusion.

The only possible way that the visor, or parts on the visor, could have caused the damage found on the forward bulkhead shown in this report, is that the damage was caused by the "visor locking lug" itself. The visor locking lug was in such case not locked with its locking pin when the visor was detached from the ship. It is impossible that the lug, still attached (locked) to the ship but detached from the visor, could have caused the damage.

It is also impossible that the "manual locking lug" could have caused the damage, even though the manual lugs seem to fit the damage quite well. It is impossible because in such scenario the manual lugs first should have left the normal position and after that perfectly entered in to the other opening in the bulkhead without causing any damage at this specific point. In such scenario the visor locking lug must have been "out of the way", i.e. unlocked. The visor should in such scenario have moved similar to what was shown in picture 1.

This analysis show, taking all the facts of the damage into consideration, that the visor starboard locking lug was not locked when the visor was detached from the ship, and that the same lug, moving upward, hit the bulkhead and caused the damage. During the scenario or thereafter, the lug was detached from the visor and in some way placed back to the locked position on the ship.

When, why and how the visor locking lug ended up back to its "normal locked position" in the forward bulkhead, is not dealt with in this report.