![]()

![]()

©

2000 The Independent Fact Group

Part one - Non-evaluated damages and misleading conclusions

Paper NF-5, the International MV Estonia Seminar, Stockholm 29-30 May 2000

In this part one:

The mating boxes on the ramp

The missing ramp railings, cut off and found at

the seabed

The preventer wires for the ramp

Category 1. Damages found by the Commission, incorrect conclusions made:

The damage on the mating boxes on the ramp

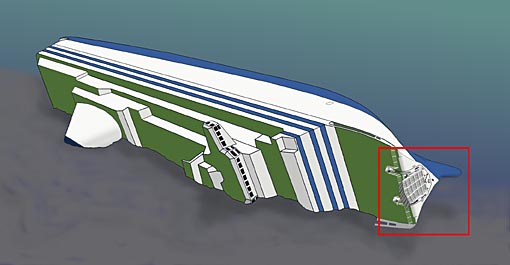

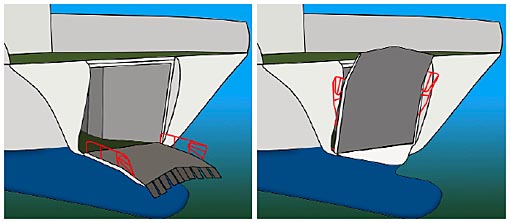

Picture 1: Ship at the seabed. Simplified drawing, perspective changed in bow area to visualise the ramp.

This is what the ship look like on the seabed. We are now to look at the bow part of the ship where the ramp is mounted.

The Commission concluded that the ramp was pulled fully open by the visor as it fell of the ship. The Commission also came to the conclusion that the visor was properly closed and locked before departure.

Picture 2: Close up of front bulkhead. Simplified drawing, perspective changed in bow area to visualise the ramp.

Here we can see the ramp slightly open in the upper part and it is also possible to see a bit of the tunnel in to the cardeck. The gap between the hull and the ramp is around 0,6 meter. The tunnel is also seen on the other picture where the ramp has been removed to illustrate the opening in to the cardeck.

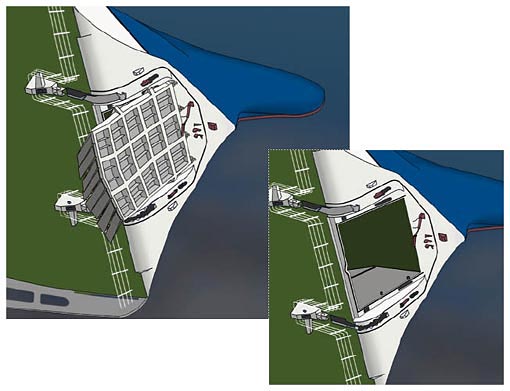

Picture 3: The ramp, from inside cardeck, as lying on starboard

side.

From this view we see the ramp from the inside. The ramp was locked with six devices, and four of them were hydraulic pins that engaged into mating boxes welded to the side of the ramp. The four mating boxes are shown here.

It is a fact that the Commission in their report chapter 8.6.5 state that the mating boxes (1) were "ripped open". They also found that the lower port side mating box was undamaged, as the locking pin for this mating box had not been fully extended.

The conclusion regarding the "ripped open" mating boxes should be seen in the light of the statement in chapter 3.3.6 where the Commission states (2) that.... "Minor routine welding repairs had been carried out on the mating boxes for the ramp locking bolts whilst the ship was in service in the Gulf of Bothnia."

By this statement it must be concluded that it used to be problems with the mating boxes that resulted in routine repairs. We can therefore not be certain what state the mating boxes had when MV Estonia left Tallinn this last evening, and it has not been concluded that the mating boxes really were undamaged before the disaster.

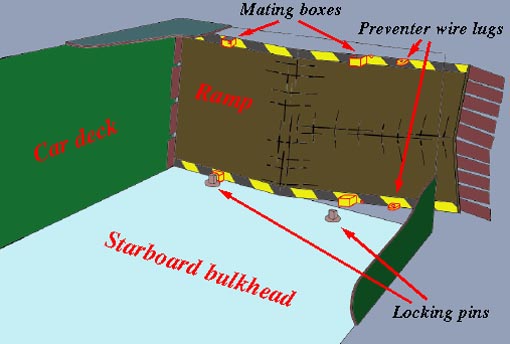

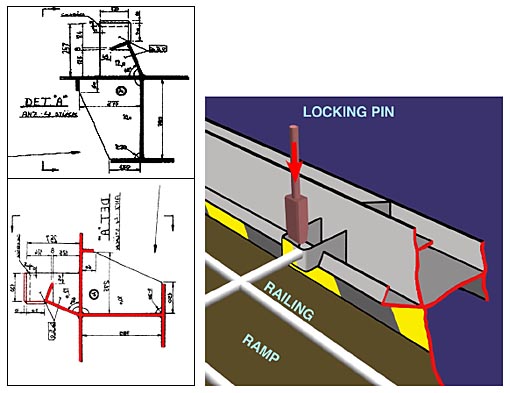

Picture 4: Simplified drawing and detail of "von Tell drawing 49111-301a". The port side lower mating box, seen from the inside of the ramp.

This picture show the cross cut of the port side ramp beam with the lower mating box, as it should look if the ramp had been undamaged.

Left top: Original drawing "von Tell" (cross cut of the ramp beam).

Left bottom: Drawing mirrored and turned.

Right: Undamaged ramp and railing.

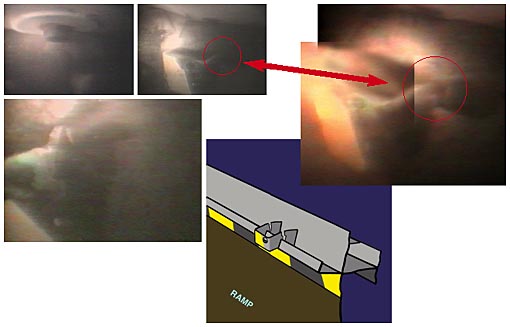

Picture 5 (see also 3): Video SHK B 40 c, Time 1.34.22 The

port side lower mating box, seen from the inside of the ramp.

This is a video print of the lower port side mating box. The mating box itself is undamaged, but close to where the mating box was welded to the ramp, there is a crack in the ramp construction (3).

It is the plates that should distribute the load from the mating box in to the ramp construction that has been damaged by at least one identified crack.

Picture 6: Simplified drawing of ramp before and after damage. The port side lower mating box, seen from the inside of the ramp.

The pictures illustrates:

to the left, the cross section of the ramp, "original design" and after the damage that bent the ramp

to the right top, the mating box "original design"

to the right bottom, the crack in the ramp construction close to the mating box.

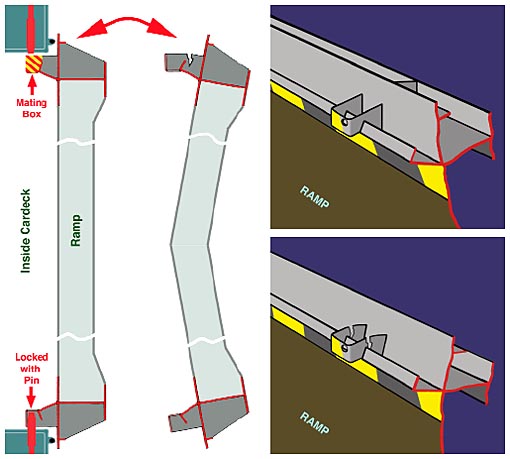

The upper port side mating box

Picture 7 (see also 3): Video SHK B 40 c, Time 1.35.23 and 1.35.54 The port side upper mating box, seen from the inside of the ramp. (The diver is holding his hand in the mating box in the left picture, bottom right corner)

Also this mating box is in fact undamaged, but the commission concluded it to be "ripped open". There are two cracks close to where the mating box has been welded to the ramp exactly in the same way as for the lower port side mating box.

[ We shall also see this on a short video. Video 1. Investigation of port side mating boxes (3) ]

The so-called "ripped open mating boxes" are the substantial evidence for the Commission scenario where the ramp was pulled to open position. Major evidence for this scenario is now found to be incorrect. The correct conclusion would have been that close to the port side mating boxes, the ramp construction is damaged by cracks in the construction. As one of the locking pins were found only partly extended, to short to have been engaged in the mating box, it seem natural to suspect that the ramp construction may have been damaged prior to the accident.

As the mating boxes are undamaged and the ramp found to be open on the wreck, the ramp may have not been properly closed when the ship left Tallinn.

It can not be excluded that the cracks close to the mating boxes were not those subject to "routine welding repairs" as mentioned. We are not going to speculate into this matter, we leave that to be a task for a new investigation group.

Category 2. Damages documented by the Commission, unidentified and not evaluated:

The missing ramp railings

On each side of the ramp there was a permanent railing.

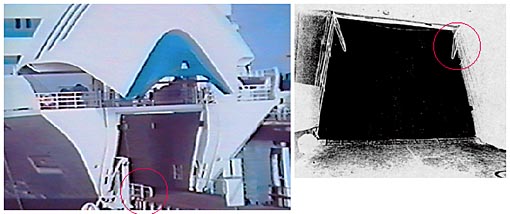

Picture 8: MV Estonia in port and to the right the closed bow ramp seen from the inside.

The railings were welded to the ramp, and as the ramp was

longer than the height of the opening in to the cardeck, the

outer part of the railings could be turned backwards inside to

fit when the ramp was closed. The railings were very close to

the bulkhead when the ramp was closed.

Last year we discovered that the railings were missing on the video recordings from the wreck, and that there were no documentation from the Commission that the railings had been removed during the inspection of the wreck. The Commission states in chapter 3.3.4 that the railings were welded onto the sides of the ramp (4). This is the only information in the report regarding the ramp railings.

If, assuming that the Commission scenario is correct, the ramp had been pulled open by the visor, the railings had followed the ramp to open position. As the ramp according to the Commission became severe damaged in this stage, let us see what would have happened with the railings.

Picture 9: MV Estonia. Simplified drawing, Ramp with railings, opened and closed.

The upper corners on the closed ramp were bent in a forward direction. On the drawing here I have illustrated what had happened to the railings if they had been on the ramp when it was damaged and fully opened.

As the railings were welded to the ramp they surely had been bent outwards when the ramp was bent and damaged. The consequence had been that they never had fit into the opening to the cardeck when the ramp closed itself during the sinking scenario. They should have been stuck between the ramp and the bulkhead like frog legs hanging out of the mouth of a snake.

As this was not the case and taken into account the damages to the ramp, the railings could never have left the tunnel of the cardeck.

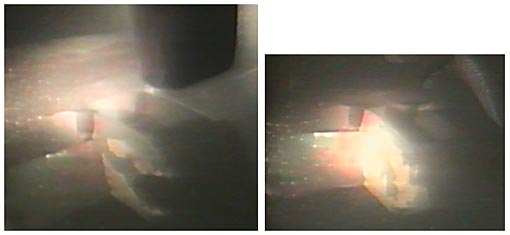

Picture 10: Video SHK B 40 c. Time 1.35.38 The port side remains of railing.

On this picture we can see one of the remains of the railing stanchion where it was welded to the ramp. This is the port side of the ramp were the short part of railing can bee seen. It has a clear cut and the removal of the railing must have been done by use of some cutting device. If ripped off, the metal would have been squeezed or the "cut" would not have been as clean as it is.

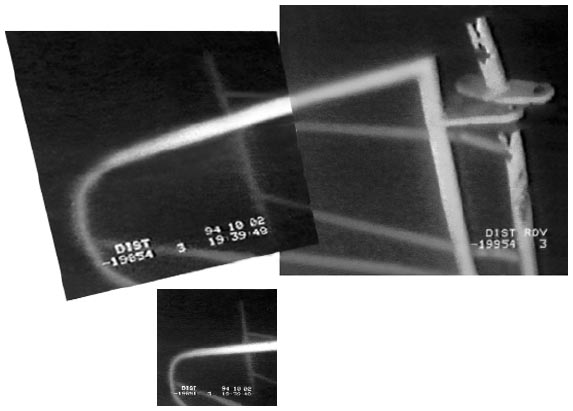

Picture 11: Video ROV 94.10.02. Video log 19.39.48. The upper

part of the starboard railing.

This picture (mosaic) show a part of the starboard railing, the turnable section, found on a video recording of the seabed close to the ship. The left picture has been edited to fit the perspective, the original is shown to the right (5).

The Commission has not evaluated why, how, or when the railings were removed from the ramp, and of course they therefore have not been able to make any conclusions as a result from these findings. The fact that the railings are detached from the ramp casts severe doubts on the Commission scenario.

Further more, still at the ramp, the Commission made other incorrect conclusions.

Category 2. Damages documented by the Commission, unidentified and not evaluated:

The preventer wires for the ramp

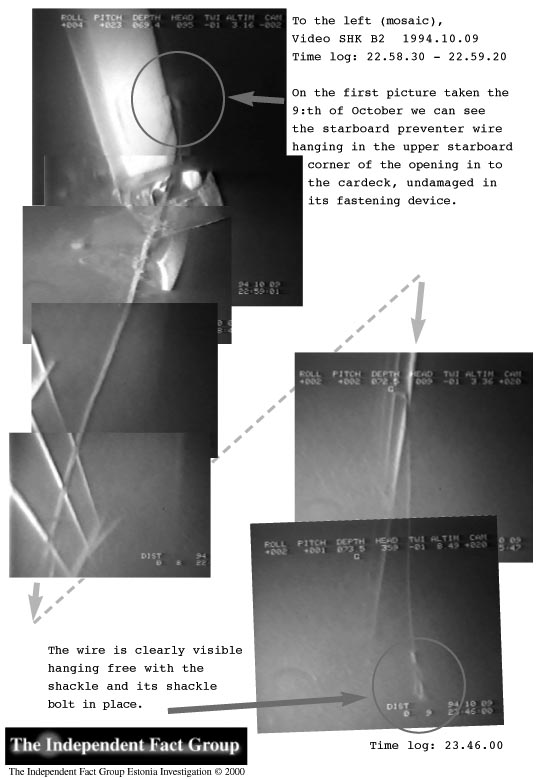

On each side of the ramp there was a "preventer wire" attached. It was to prevent the ramp when fully opened, from falling down on to the little forepeak deck under and in front of the ramp. The Commission has in chapter 8.5.4, I presume based on the video recordings, come to the conclusion that the preventer wires had detached from the lugs on the ramp (6). On at least two video recordings from the wreck the starboard preventer wire can bee seen undamaged with its shackle and shackle-bolt in place.

Picture 12: The undamaged preventer wire shackle and fastening device.

On the first picture taken the 9:th of October (7) we can see the starboard preventer wire hanging in the upper starboard corner of the opening in to the cardeck, undamaged in its fastening device. The wire is clearly visible hanging free with the shackle and its shackle bolt in place.

Picture 13: Video RW/SEMI1/EST/D/014 (Also as SHK B 40 e).

Time 1.13. The undamaged starboard preventer wire and shackle.

Here we can see the shackle in a close-up. On the video (8) the diver is working near the ramp. He tries to reach a cable sent down from the surface and in order to do so he uses the preventer wire to hang on to. The wire is complete with shackle and shackle-bolt in place.

It has not detached from the ramp as stated by the Commission as evidence that the ramp fell down to the little forepeak deck in front of the ramp. It must have been detached manually as the shackle-bolt has been put back into the shackle.

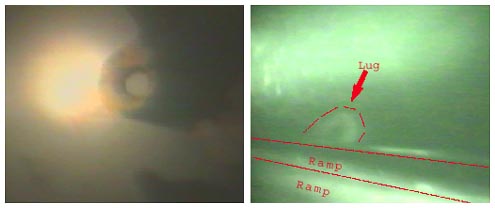

| Starboard preventer wire lug | Port preventer wire lug |

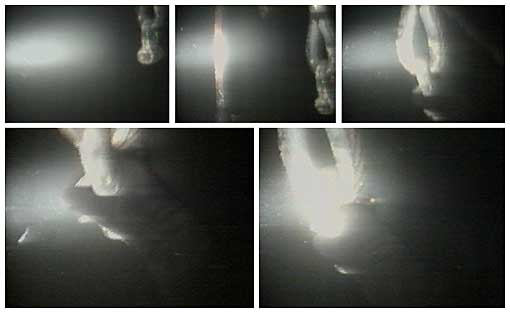

Picture 14 (see also 3): Video SHK B 40 c. Time 0.59.35 (starboard lug) 1.30.40 (port lug). The undamaged starboard and port preventer lugs.

Here we can see the starboard and port side lugs on the ramp, where the preventer wires used to be mounted. They are both undamaged, which prove that at least the starboard preventer wire that we have found undamaged with the bolt in place, did not detach from the ramp.

It is of course extremely unfortunate that central evidence used to conclude the Commissions only scenario proves to be incorrect.

But, there is worse to come.

Part II

(1) JAIC 8.6.5 The ramp attachment and locking devices...."Three

of the four side locking bolts were in their extended position

and the mating boxes on the ramp side beams had been ripped open.

The port side lower locking bolt was only partly extended and

its mating box was undamaged." (back)

(2) JAIC 3.3.6 Surveys, maintenance, damage and repairs...."Minor

routine welding repairs had been carried out on the mating boxes

for the ramp locking bolts whilst the ship was in service in

the Gulf of Bothnia." (back)

(3) Video SHK B 40 c: Time 1.34.22. The port side lower

mating box, seen from the inside of the ramp. (back)

(4) JAIC 3.3.4 Detailed technical description of the bow

loading ramp...."Raised bars were welded onto the sides

of the ramp. Fixed railings were mounted on each side." (back)

(5) Video ROV 94.10.02. Video log 19.39.48. The starboard

railing found at the seabed. (back)

(6) JAIC 8.5.4 Ramp damage...."The wires preventing

the ramp from falling down to the forpeak deck had detached from

the lugs on both sides of the ramp." (back)

(7) Video SHK B2 1994.10.09: Time log 22.58.30 - 22.59.20.

The Starboard preventer wire can be seen hanging in the upper

starboard corner of the opening in to the cardeck, undamaged

in it's fastening device. Time log 23.46.00. The preventer wire

and it's undamaged shackle hanging down from the wreck.

(back)

(8) Video RW / SEMI1 / EST / D / 014 (Also as SHK B

40 e): Time 1.13. The preventer wire and shackle is shown several

times, undamaged with the shackle bolt in place. The diver uses

the wire to climb and hold on to. (back)